Keyword Search:

Omnia Wideslab

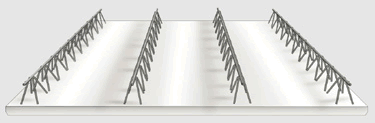

The basic OMNIA panel is called OMNIDEC

and incorporates lattice girder at 600 c/c in a 50mm thick pre-cast concrete panel which is reinforced with steel bars 8-14mm dia at 50-300mm centres depending on the requirements of the loading condition. wideslab

omnia precast concrete permanent formwork systems from hanson concrete products

With the lattice spaced at 600mm c/c, the panels will support themselves, the in-situ reinforcement, in-situ concrete and construction loads (1.5kN/m2) for approx. 2.5m without the need for temporary supports.

omnia precast concrete permanent formwork systems from hanson concrete products

Although usually designed by Hanson Concrete products as participating, Omnia panels can be supplied purely as permanent formwork, in which case the responsibility for the working condition design would be by others.

Dimensions

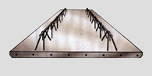

The panels are manufactured in depths from 50-75mm thick to suit a variety of exposure and structural requirements, with cover to the reinforcement varying from 20 to 40mm as required.

Shape

ll panels are cast in steel moulds to length by introducing a

stop-end into the mould. The long edges are formed with a chamfer to the underside, so that when placed adjacent to each other, the effect of a birds-mouth joint at regular intervals on the soffit can be seen.

omnia precast concrete permanent formwork systems from hanson concrete products

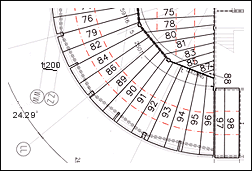

By varying the position of the stop end by introducing special side forms the panels are designed to suit the shape of the building and as a result we can cater for structures of quite complex floor layouts (as can be seen below), although we would prefer an occasional right angle!

Maximum Spans

Spans of up to 11m are possible, but are limited by the permitted span depth ratio. Unlike other floor systems, the Omnia system benefits greatly from any continuity over supports. Please note that vertical cavities between residential dwellings and also some gable conditions may cause a generally continuous design slab to be simply supported in isolated areas. When designed in a continuous situation, the permutations of spans and loadings are too numerous to display, however the graphs shows the maximum spans available in a 1 or 3 span situation for slabs of varying depths.

In all of the above cases a standard lattice is cast into the panel at 600 c/c, and temporary propping would be required at maximum 2.5m c/c.

Click here to view the graph.

Reduced Propping

The graph is based on a 50mm panel with 20mm cover to the reinforcement and lattice, with allowable spans taking account of crack widths, defections, top bar and diagonal bar strengths.

Click here to view the graph.

Home Page | Omnidec | Bridge Deck | Solution Finder | Downloads | latest news | Contact Us

Variationsclick links below to view details.OmnicoreOmniedgeOmniliteOmnithermErectionclick links below to view details.Lifting & PlacingBearingProppingBenefitsclick links below to view details.ErectionSoffit QualityProgressive CollapseNon-Standard ShapesStructural FlexibilityInsulation